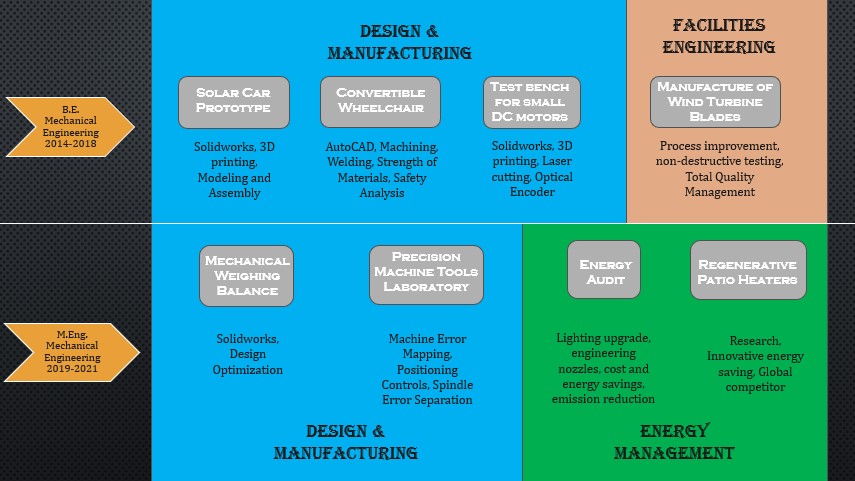

Here is an overview of the projects I’ve completed so far. All my projects are focused on my areas of interest: Design, Manufacturing, and Energy Conservation.

Mechanical Engineer (Motors) – Stanley Black & Decker – Towson, Maryland, USA

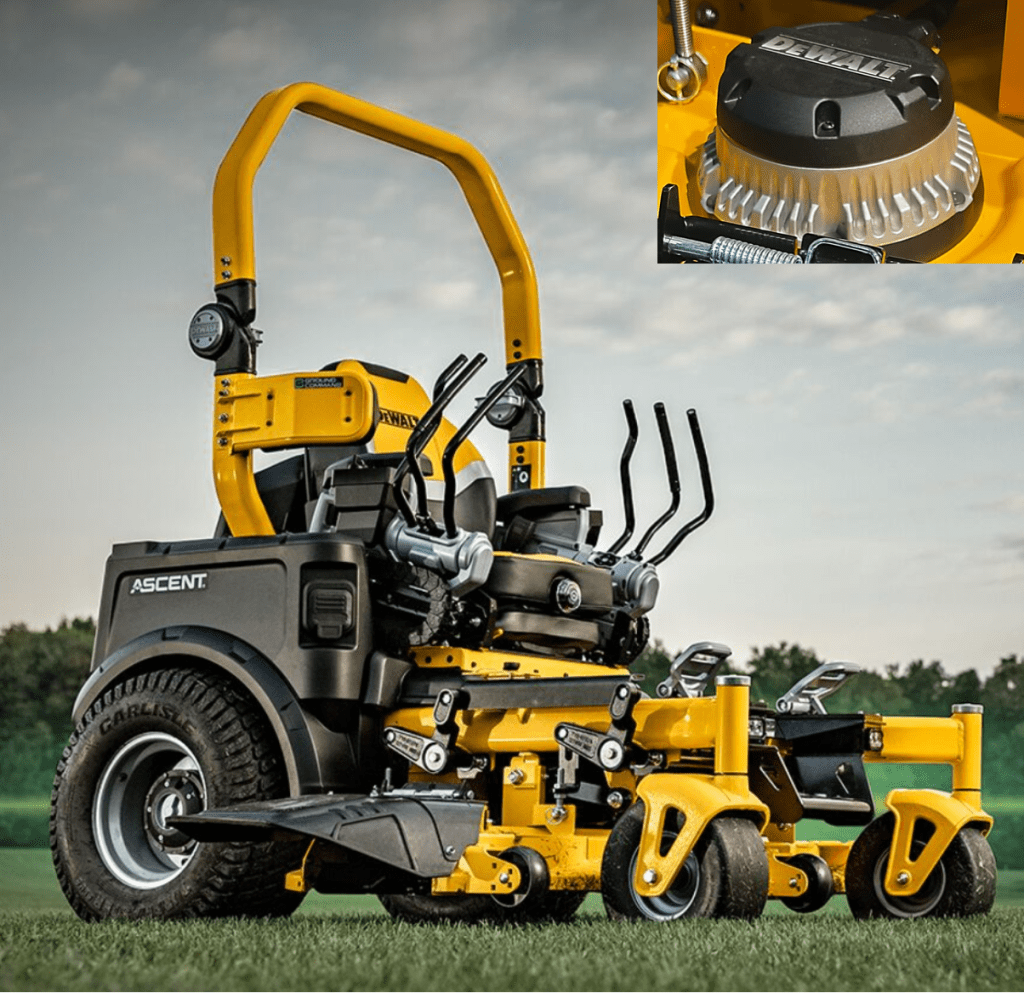

Supported full life cycle development of motors from concept to prototype to full production for a new-to-market zero-turn commercial lawn mower to be launched in 2025.

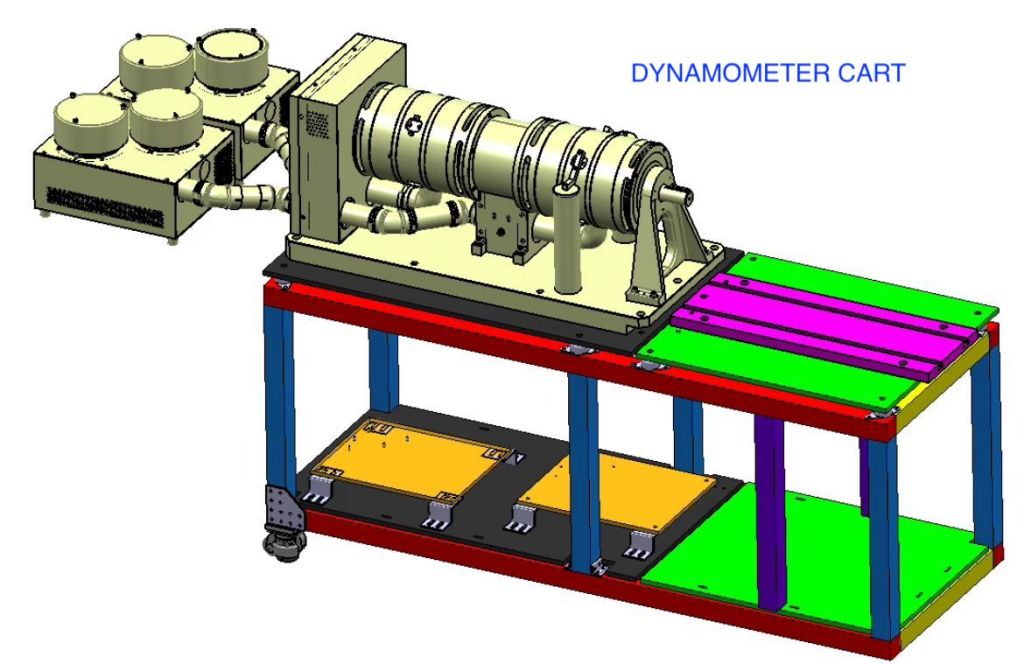

Designed fixtures such as flux fixture, dynamometer cart, back-to-back motor test rig using CATIA V5 CAD software and GD&T and assembled them for new product development of different stack-length motors

Led the implementation of MPS chip indirect sensing in 140mm Outer Rotor motor platform using calibration software which led to an increase of motor efficiency by 10%

Organized and attended multiple prototype builds in Reynosa, Mexico. Built more than 250 motor prototypes that were integrated into lawn mowers for cut testing and feedback. Performed root cause analysis of motor failure for failure modes such as improper motor calibration, component interference, and component high stress concentration.

Worked with Advanced Manufacturing Team, troubleshooted motor ‘End of Line Tester’ and coordinated hardware/software solutions with the vendor in Wisconsin

Analyzed and plotted the variance of motor back drive angles for hall signals U,V, and W using Minitab to find the reason for reduction in motor performance

More on my projects..

1. Lean Engineering Project at Paradigm Metals Ltd

Worked for this company in the capacity of a lean engineer as part of course project on ‘Lean Engineering’. Performed Pareto Analysis, studied the current ASIS model, drafted the TOBE model, and implemented lean engineering practices to remove 7 forms of wastes in the facility using Total Productive Maintenance (TPM), Overall Equipment Effectiveness (OEE), and process modeling

Reduced lead time from 21 days to 15 days through a lean implementation plan using tools such as IDEF0, IDEF3, Value Stream Map (VSM), Analysis of Alternatives (AoA), Task Engineering, 5S, Six Sigma (6σ), Heijunka Box, Statistical Process Control (SPC), and DMAIC

LOCATION: Hutto, Texas, USA

MENTOR: Dr Mike Graul (Associate Professor at Texas A&M University)

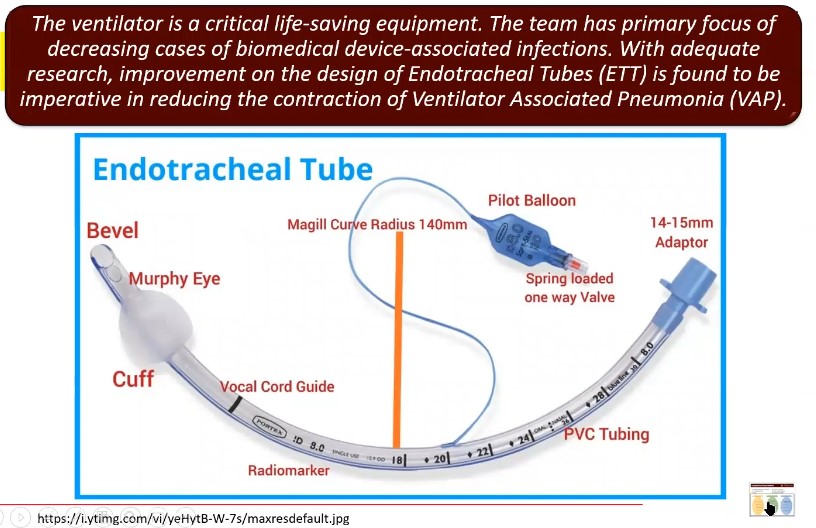

2. Advanced Product Design of Novel Endotracheal Tubes for Ventilators

Worked on improvising the design of existing Endotracheal Tubes used in Ventilators as part of course project on ‘Advanced Product Design’. The Solution Neutral Problem Statement (SNPS) of this project is to design a means to minimize biomedical device-associated infections through prolonged mechanical ventilation targeted for patients needing support for breathing

Designed anatomically shaped endotracheal tubes dip-coated in BCP3 solution to reduce Laryngeal injury by 40.86% with P value less than 0.001

Conducted risk analysis using Design Failure Mode and Effects Analysis (DFMEA), Design for Excellence (DFx) engineering principles, and Root Cause Analysis (RCA) on antimicrobial endotracheal tubes to lower the chances of biomaterial associated infections in ventilators

LOCATION: Texas A&M University, Texas, USA

MENTOR: Dr Richard Malak (Associate Professor at Texas A&M University)

3. Bio-inspired Design of Indoor Sports Shoes

Worked on the bio-inspired design of novel indoor sports shoes inspired from mushroom-shaped microstructures on the outsole of the shoe to provide the user enhanced grip and to prevent slipping. The outsole has been optimized for peak user comfort and cushioning effect

LOCATION: Texas A&M University, Texas, USA

MENTOR: Dr Astrid Layton (Assistant Professor at Texas A&M University)

4. Schneider Electric Global Virtual Student Experience

Participated in Schneider Electric’s exclusive program of 100 students selected to learn about business model and culture, network with top leaders, actively participate in career development workshops, and completed two learning courses:

Services track – Learning about how Schneider Electric maintains and improves system reliability, productivity, comfort and efficiency. Training on services business including power, automation and control, and building life cycle service solutions.

Sales track – Discovering Schneider Electric’s customers and partners, understanding the value chain and learn how to influence a business.

WEBSITE: https://app.jobvite.com/TalentNetwork/action/campaign/w/NzI5ODQ

5. Schneider Electric Go Green Challenge

Our project idea titled ‘Regenerative Patio Heaters‘ aimed at reducing the energy consumed by patio heaters by re-using waste heat from kitchen equipment.

We advanced up to the semi finals event of the Schneider Electric Go Green Challenge.

LOCATION: Dallas, Texas, USA

MENTOR: Angela Carver (Performance Assurance Consultant at Schneider Electric)

WEBSITE: https://gogreen.se.com/en

6. Energy Audit at Maco Manufacturing

Performed an inspection survey at Maco Manufacturing as part of course project on ‘Energy Management in Industry‘.

Analysed energy flows for energy conservation within the facility and drafted an energy audit with the following energy recommendations:

a. Use more efficient lighting: Conversion of metal halides to LED

b. Use synthetic lubricants for motors

c. Disconnect unused ballasts

d. Use engineered nozzles

LOCATION: Temple, Texas, USA

MENTOR: Dr. Bryan Rasmussen (Professor at Texas A&M University)

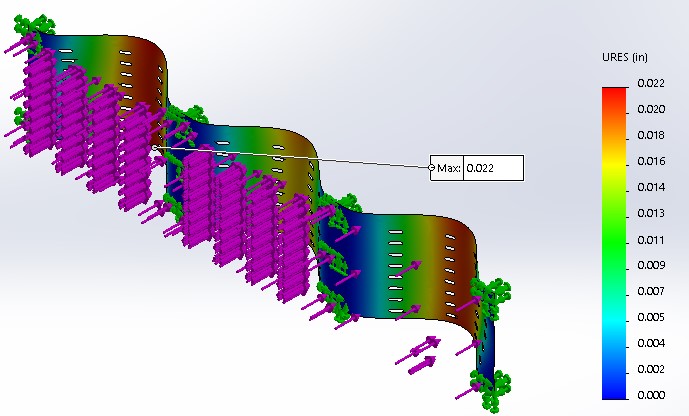

7. Advanced Computer Aided Engineering (CAE) models

Starting with the model on the top-left, a mechanical weighing balance was 3D-modeled. A complete report on part development, assembly development, motion analysis video, tolerance analysis, part drawings, and assembly drawing of the mechanical weighing balance were delivered.

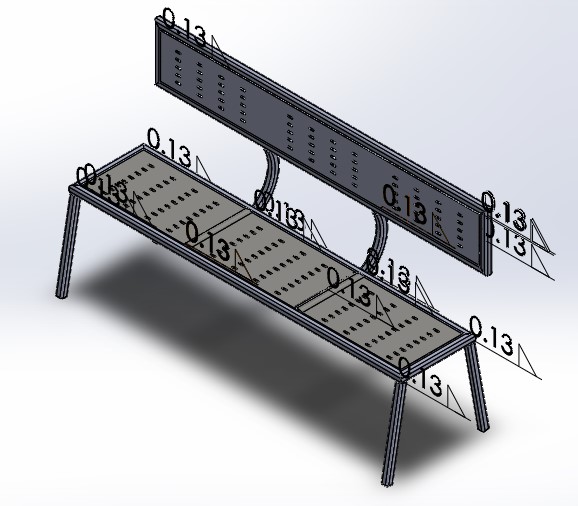

As seen in the model on the top-right, Static Finite Element Analysis (FEA) was performed on a bench seat to design a robust bench model under the given Factor of Safety (FOS) and other design requirements.

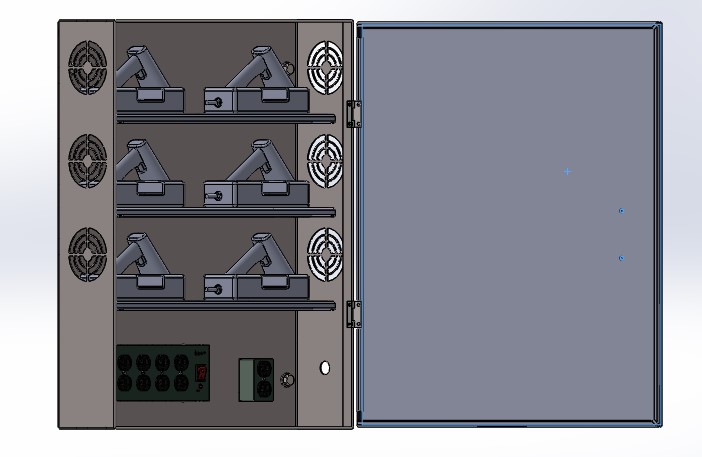

The model on the bottom-left depicts a cabinet assembly created to contain 6 scanners and a docking station with vents provided on either sides of the cabinet for ventilation

The model on the bottom-center shows an engraved sign made using Autodesk Fusion 360 software

The model on the bottom-right displays a bench (with weldments for support) that can seat three people comfortably

MENTOR: Heather Lewis (Lecturer at Texas A&M University)

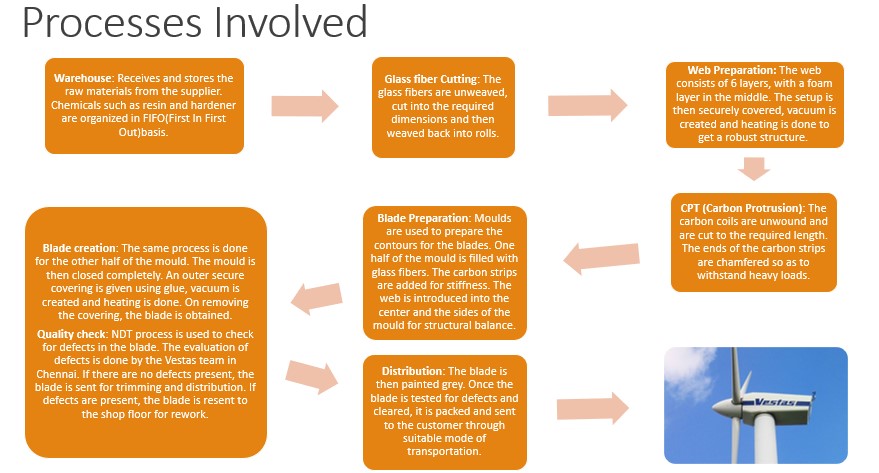

8. Wind Turbine Blade Manufacture

Observed the step-by-step procedure involved in manufacturing wind turbine blades while working as a facilities engineering intern.

Identified areas of improvement, improved manufacturing methods, recommended equipment upgrade, implemented 5S-approach, and Kaizen method of process improvement for better operational efficiency.

LOCATION: Ahmedabad, Gujarat, India

MENTOR: Prashanth Kumar (Lead Engineer at Vestas)

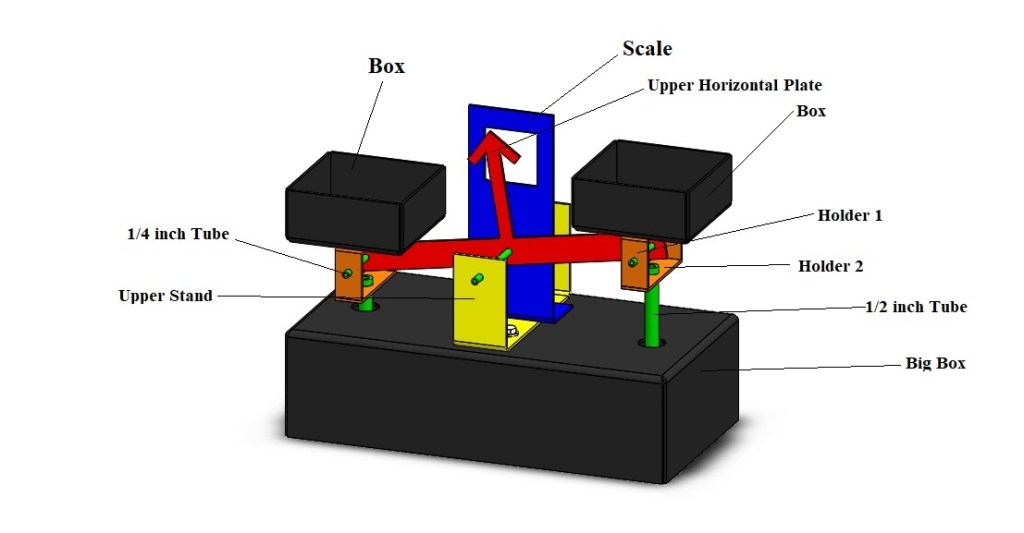

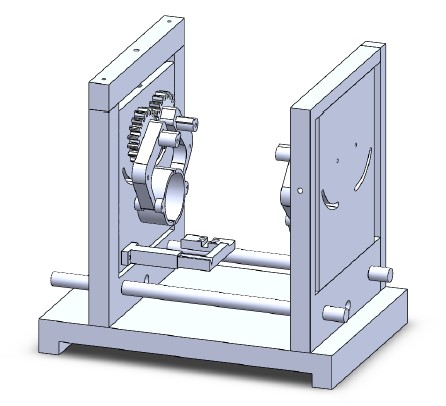

9. Test bench prototype for small DC motors

A test bench is used to evaluate the parameters of a test motor by coupling it on the bench with a calibration motor.

Conventionally, test benches are used to evaluate test motors of a single size only. In our newly designed test bench, test motors of variable sizes can be evaluated by using a combination of two adjustable test plates and a lead screw system.

The objective of the project was to design and create a 3D-printed test bench for DC motors of outer diameters 10mm to 50mm to determine motor angular direction and speed parameters.

LOCATION: Heilbronn University, Baden-Wurttemberg, Germany

MENTOR: Dr. Ansgar Meroth (Professor of Automotive Systems engineering at Heilbronn University)

10. Convertible Wheelchair

Designed and fabricated a multi-purpose wheelchair that can be used as a recliner and a stretcher. This was achieved with the help of an innovative curved beam mechanism that makes multiple orientations of the wheelchair possible.

This project aimed at eliminating the user’s need to move to a bed every time he/she needs to sleep. It was the capstone project for my undergraduate program.

LOCATION: Anna University, Tamil Nadu, India

MENTOR: Dr. Moses Raja (Head of mechanical department at Anna University)

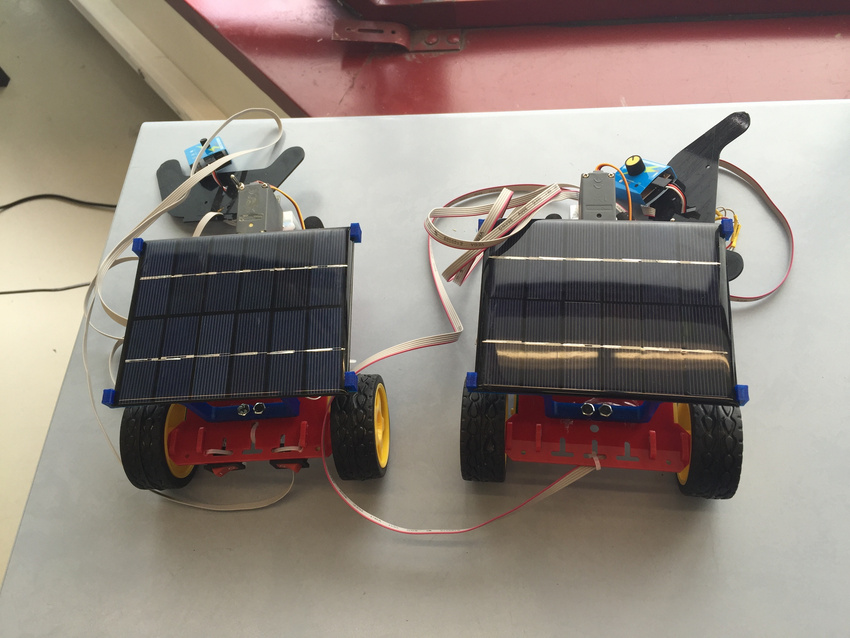

11. Solar Car Prototype with Wired Remote Control

Renewable energy is one of the most important power sources in the coming future. The objective of our project was to design and create 16 car prototypes using 3D-printed components.

These prototypes used solar power as their secondary power source and were controlled by wired remote devices.

This project involved the collaboration of engineering students from different engineering disciplines, namely, Mechanical, Electronics, and Electrical engineering. We successfully created 16 working solar car prototypes. I headed this interdisciplinary team as their project leader.

LOCATION: ICAM University, Lille, France

MENTORS: Leo Lecouche (Professor at ICAM University) and Remigius Praveen (Professor at Anna University)